Flexibility and versatility – Slinging points from norelem

The main types of rigging element

Hoist screws

Hoist pins

Swivel ring bolts

D-rings

Ring bolts

Hoist rings,

Locating bushes for lifting pins

High safety standards: A decisive factor in favour of rigging elements

Increase your efficiency with our anchor points

Flexibility and versatility – Slinging points from norelem

Anchor elements are special fastening points used in hoisting technology and load management. They belong to the lifting gear product family and are used as safety lifting and securing equipment in industry. They are designed to hold loads securely and to be flexible in use. The most commonly used rigging elements include hoist screws, ring nuts, shackles and swivel ring bolts.

Some anchor points, such as hoist rings, allow loads to be moved and swivelled. Lifting pins, on the other hand, provide maximum flexibility. The wide range of applications make rigging elements essential for safe and efficient load handling in industry and construction.

The main types of rigging element

norelem offers you a range of different, application dependent rigging elements for attaching and flexibly handling loads. These include hoist rings, shackles and lifting pins and each of these standard parts fulfils a specific function and is suitable for specific applications. In addition to the diversity of our range, we rely on robust materials such as stainless steel, steel or Q&T steel.

To give you an overview of our range, we will now take a closer look at the individual standard parts.

Hoist screws

Hoist screws are bolts with a thread and attachment point and are used in toolmaking and machine construction. Hoist screws are used as aids to secure or transport heavy loads. They are used to lift, turn and position large and heavy components. Our hoist screws are made from steel CK45 (1.1191), which has a high tensile strength of around 700 N/mm². Their high strength means that these screws can carry loads of up to 2500 kg.

The hoist screws are black oxidised, which gives them additional corrosion protection and makes the surface more resilient. The manufacture and dimensioning of the screws are based on VDI guideline 3366.

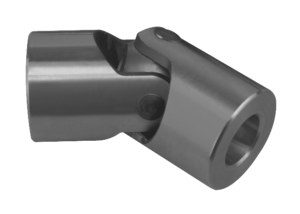

Hoist pins

Hoist pins are used to carry and stabilise heavy loads such as large tools or machine parts. The cylindrical form of the attachment point enables secure anchoring and support of heavy loads, making them indispensable for mounting or tilting heavy tools.

When four hoist pins are used simulaneously, two of the should be able to bear the entire weight of the tool. The other two serve to stabilise and support the safe handling of the load, especially when the tool is being tilted. This arrangement ensures an even distribution of the load, thus increasing both safety and user-friendliness..

The hoist pins are made of 1.1191 (CK45) steel. This steel is characterised by its high tensile strength of around 700 N/mm². This makes the hoist pins particularly resilient and durable. The surface of the pins is black oxidised to provide protection against corrosion.

The norelem hoist pins fulfil the requirements of VDI directive 3366. This ensures that the standard parts are manufactured to a uniform quality standard.

With a load capacity of up to 8000 kg, these hoist pins are designed for use in heavy industrial applications. For a simple installation, the pins are supplied with matching screws (cap screws) that enable easy and secure fastening.

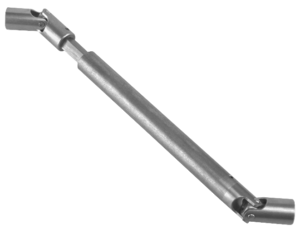

Swivel ring bolts

Swivel ring bolts are swivelling fastening elements that prevent slings from twisting. These bolts are made of high-quality grade 8 steel and have a hard-wearing red plastic coating. The swivel ring bolts from norelem have a load capacity of up to 8 tonnes and consists of a threaded attachment element with ball bearing. Thanks to this design, it can take full loads from all sides and thus offers 4-fold safety factor against possible breakage in all load directions.

The ball bearing construction ensures that the swivel ring bolt can be rotated through 360 degrees. These standard parts can be rotated even under full load, which is a great advantage for many lifting and securing tasks.

D-rings

The norelem D-rings fall under the lifting accessories product family. The definition of an anchor point for the machine builder is a screw-on or weld-on fastening element. These anchor points enable load-bearing elements (such as chains) to be securely attached to the load being lifted.

Anchor points are important equipment designed for daily use. Both tools and machines can be transported safely using them. The components can also be used for lashing goods, as restraints and as a movement-supporting function during transport.

Above all, the quick installation of weld-on D-rings give these standard parts a major advantage. In addition, D-rings can take loads from any direction. The 4x safety factor means that the rings have an exceptionally high level of resistance to breakage. This increases reliability and safety, even with complex loads.

Ring bolts

Ring bolts are always used when heavy loads need to be taken up by a connecting element. They are ideal as load handling equipment in mechanical engineering and on construction sites.

Our customers favourites:

- DIN 580 ring bolts

- Ring bolts similar to DIN 580

- Stainless steel revolving high-strength ring bolts

- High-strength rotatable grade 10 ring bolts

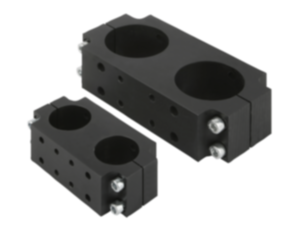

Hoist rings,

Hoist rings are mechanical elements used to secure and lift loads. They have high load-bearing capacity. These standard parts are used in various applications, particularly in construction and mechanical engineering.

During production, each hoist ring type is subjected to a load capacity test. This ensures a 5x safety factor. In addition, a visual inspection is carried out to ensure that the components are in perfect condition.

For installation purposes, a safety data sheet is included with each hoist ring that contains important information about the installation requirements. When handling hoist rings, it is important to work carefully and to avoid impact loads.

Special types of hoist rings

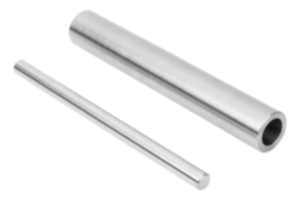

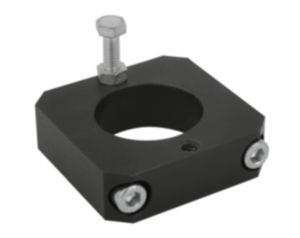

Locating bushes for lifting pins

Locating bushes are widely used in the machine and plant construction industry. They are primarily used as a safe and effective adaption option for lifting pins. Their design enables simple and reliable installation in a wide variety of host materials.

The norelem locating bushes are made of high-grade stainless steel, or more precisely 1.4542. This is characterised by its high strength and corrosion resistance. In addition, the locating bushes are hardened i.e. they have been strengthened by a special heat treatment process. These hardened versions ensure high resistance to abrasion and wear, enabling the bushes to be used in demanding applications.

Another outstanding feature of the locating bushes is their versatility. They can be used in both thick and thin-walled parts and are ideal for mounting in blind holes.

Locating bushes in the norelem hoist material range:

- Stainless steel locating bushes for lifting pins

- Flat stainless steel locating bushes for lifting pins

High safety standards: A decisive factor in favour of rigging elements

Rigging elements offer numerous advantages that make them indispensable components. We have summarised the individual advantages for you to give you a rough overview.

- High load capacity for heavy loads: The standard parts are designed for high loads and offer a load-bearing capacity into the double-digit tonne range. This makes them ideal for heavy industrial applications. At norelem, the load capacities range from 96.9 kg to 8500 kg (8.5 tonnes), making them highly versatile.

- Durable and resistant to wear and corrosion: The use of robust materials makes the standard parts resistant to wear and corrosion, making them particularly suitable for demanding environments.

- Safety and stability: Rigging elements also serve as safeguards against falling objects. They ensure a safe and stable connection between the load and the lifting gear. This way, they minimise the risk of accidents, which is of great importance for occupational safety.

- Flexibility and versatility: The wide selection of different types (e.g. hoist screws, ring nuts, shackles etc.) permits anchor points to be used flexibly to suit the application..

- Easy installation and use: Many rigging elements are easy to install and use, saving time and effort.

- Rotating and swivelling functions for flexible use: Elements such as swivel ring bolts and swivel hoist rings permit the load to rotate freely, which increases mobility and prevents the slings twisting.

- A wide range of mounting options and adaptability to various applications: The various designs and mounting options increase the range of applications and adaptability in different load scenarios.

- Strict testing and certification according to standards and quality grades: The rigging points are tested and certified according to strict standards and regulations, such as the DIN standards or quality grades. A quality grade provides information about the material quality and load capacity, so that users can be sure that the rigging elements meet the highest standards.

Adherence to high safety standards ensures safe use of the rigging elements and minimises the risk of accidents.

Increase your efficiency with our anchor points

norelem is an excellent choice for purchasing rigging elements. We offer a comprehensive range of products and exceptional quality. Our range includes numerous hoisting elements, including hoist screws, ring nuts, swivel ring bolts and shackles, which have been developed for a variety of lifting and safety tasks. This diversity enables the optimal product to be selected for each application and a tailor-made solution to be found.

A major advantage of choosing norelem is the high quality standard that the company ensures. In addition, rigging elements from norelem are designed for high loads and cover load capacities well into the double-digit tonne range. This makes these standard parts ideal for heavy industrial applications where safety and robustness are essential. The ease of installation, especially by the weldable D-rings, also contributes to efficiency and user-friendliness.

In summary, norelem not only offers high-quality rigging elements, but is also a reliable partner for safety and quality.

If you have any questions about our hoisting elements or require further information, please do not hesitate to contact us! Our competent team is always at your disposal and will be happy to help you. Contact us directly, we would be delighted to hear from you!