Grease nipples from norelem

Grease nipples are components that have a thread for screwing in or a spigot for pressing in as well as the actual grease nipple. They are used in machine and vehicle construction and on agricultural and construction machines. Here they ensure that drive shafts, axles, bearings and threads can be regularly lubricated.

Operating principle

Grease nipples enable the positive fit of a grease gun. Filling the lubrication point via the grease nipple, also known as greasing, is a simple process. The grease nipple is connected to the mouthpiece of a grease gun, a pusher gun or another suitable application equipment. The mouthpiece fits positively onto the grease nipple. When the grease gun is operated, the lubricant is introduced into the lubrication point under pressure via the grease nipple. Firstly, the cavity in the grease nipple is closed by a spring-loaded ball. Only when the pressure via the attached grease gun is high enough does the ball check valve open and the lubricant flows past the ball into the inside of the lubrication point. If the grease gun is removed from the grease nipple, the pressure also drops. The ball can return to its original position and close the grease nipple again. This protects the lubrication point from dirt and the effects of the weather. At the same time, the lubricant introduced is prevented from escaping again.

Versions from norelem

The range from norelem includes conical head grease nipples acc. to DIN 71412, button head grease nipples acc. to DIN 3404 and flush type grease nipples acc. to DIN 3405. Accessories are also available.

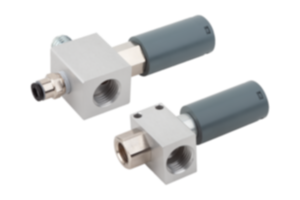

Conical head grease nipples acc. to DIN 71412

Conical head grease nipple acc. to DIN 71412 are also called conical grease nipples. They are equipped with a conical (tapered) thread and are suitable for lubrication points that need to be lubricated frequently and reliably. Due to their various application possibilities, they are one of the most widely used types of grease nipple. The versions are subdivided as follows:

- Conical head grease nipple form A with hex head, straight head

- Conical head grease nipple form B with hex head, angled head 45°

- Conical head grease nipple form C with hex head, angled head 90°

- Conical head grease nipple form D with square head, angled head 45°

- Conical head grease nipple form D with square head, angled head 90°

The conical head grease nipples are made of galvanised steel or stainless steel 1.4305. They are available with different thread sizes and are available with a pipe thread or metric tapered thread.

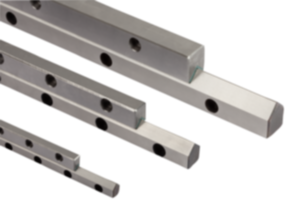

Button head grease nipples acc. to DIN 3404

Button head grease nipples acc. to DIN 3404 are also called flat grease nipples. Due to their design, they ensure a high lubricant flow rate. Button head grease nipples are therefore particularly suitable for lubrication points that require a large lubricant chamber. Due to their stable design, they are preferably used on machines with high loads.

Button head grease nipples are made of galvanised steel or 1.4305 stainless steel. The norelem range includes various thread sizes and thread types such as pipe threads or metric tapered threads.

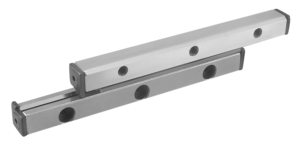

Flush type grease nipples acc. to DIN 3405

Flush type grease nipples acc. to DIN 3405 are also called flush grease nipples. They are particularly suitable for flush or recessed installation. The flush type means that the required lubrication is also possible in places that are difficult to access. The versions are divided into:

- Flush type grease nipple form A with hex head, straight head,

- Flush type grease nipple form B with square head, angled head 45° and

- Flush type grease nipple form C with square head, angled head 90°.

Flush type grease nipples from norelem are made of galvanised steel or 1.4305 stainless steel. They are available in various thread sizes and can be ordered with a pipe thread or metric tapered thread.

Accessory articles

The norelem range of technical accessories and equipment for the production environment also includes items such as protective caps for conical head grease nipples. Suitable for all conical head grease nipples acc. to DIN 71412, these caps protect the conical head of the grease nipple from contamination. The lubrication caps are available in different colours, which is used to identify lubrication intervals, among other things.